Our Equipment

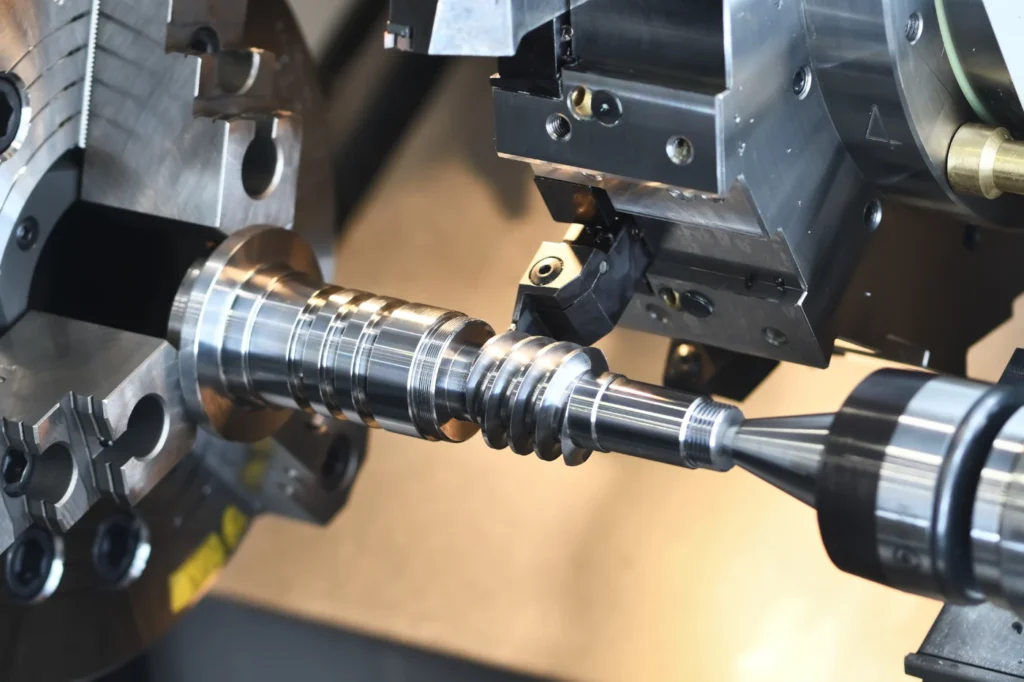

At DeYoung Machine Works, we invest in advanced CNC technology to deliver precision, efficiency, and repeatability across every job. Our equipment lineup includes multi-axis mills, high-speed lathes, and inspection systems that allow us to meet tight tolerances and complex geometries with confidence.

From prototype to production, our machines are calibrated, maintained, and programmed to perform at the highest level—giving our customers consistent results and faster turnaround times

State-of-the-Art Facility

- CNC Machining Centers: Multi-axis vertical mills and turning centers with 4th axis capabilities for complex, high-precision parts

- Automated Production Support: Automated sawing center, and bar feeders for efficient material handling and repeatability

- Advanced CAD/CAM Integration: Surfacing and solid modeling capabilities to streamline programming and improve accuracy

- Certified Inspection Tools: Precision gauging equipment calibrated for ISO compliance and traceability

- Strict Quality Control: Documented procedures ensure full certification of materials and specifications on every order

Let’s Work Together

Whether you need a dependable source for repeat production or a shop that can tackle challenging prototypes, we’re ready to help.

Contact us today to request a quote or schedule a facility visit.